- August 27, 2025

India, being an agricultural economy, produces millions of tons of crop residues each year. Rice husk, wheat straw, sugarcane bagasse, cotton stalks, and corn cobs often end up being burned in open fields. This practice creates severe air pollution, adds to carbon emissions, and deteriorates soil fertility. One of the most effective ways to solve this problem is biomass pelletization.

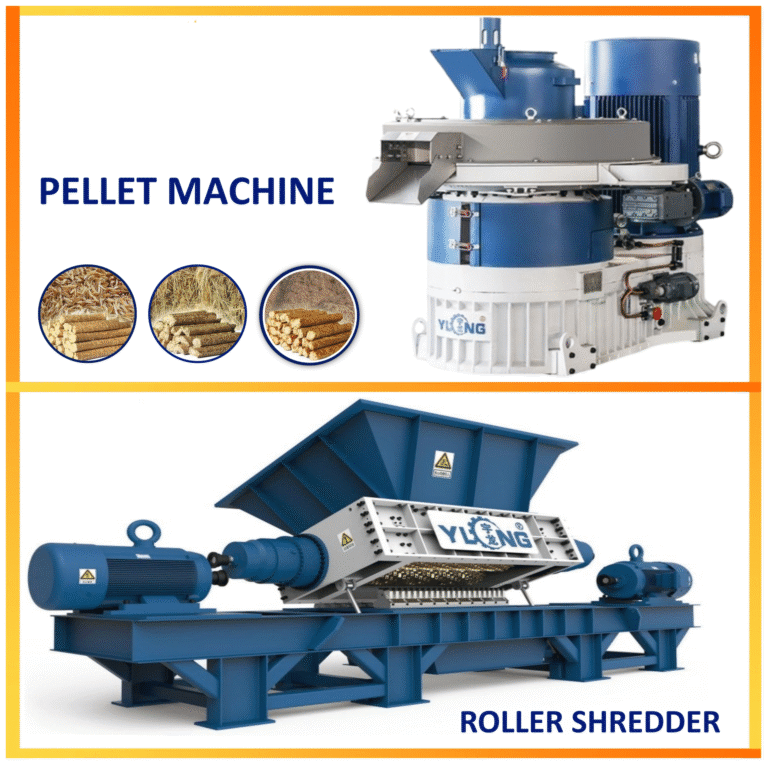

This is where Yulong-Gattuwala, a leading pellet machine manufacturer, comes into the picture. Their innovative biomass pellet technology is helping Indian farmers turn waste into wealth while fighting pollution.

🌾 The Challenge of Agro-Waste in India

Every harvesting season, thousands of farmers face the challenge of disposing of crop residues. Since there is limited awareness and infrastructure for recycling, many resort to stubble burning.

• In Punjab and Haryana alone, millions of tons of rice straw are burned annually.

• This leads to smog, respiratory illnesses, and increased greenhouse gases.

• Valuable organic matter that could enrich the soil is lost.

Clearly, India needs a sustainable alternative—and biomass pellets provide exactly that.

🔥 Why Biomass Pellets are a Game-Changer

Biomass pellets are made by compressing agricultural residues into small, dense energy units. These pellets are:

• Eco-friendly: They burn cleaner than coal, reducing air pollution.

• High in efficiency: With high calorific value, pellets are suitable for power plants, industries, and boilers.

• Cost-effective: Farmers can earn revenue from waste instead of spending on disposal.

• Renewable: They promote a circular economy by converting waste into green energy.

⚙️ Yulong-Gattuwala’s Role in Cleaner Farming

Yulong-Gattuwala provides world-class biomass pellet machines that are designed for Indian conditions. Their technology ensures that even tough crop residues like rice husk and sugarcane bagasse can be efficiently processed into pellets.

Key Benefits for Farmers:

1. On-Site Waste Management – Farmers can process residues locally instead of burning them.

2. Additional Income Source – Selling biomass pellets provides extra earnings.

3. Better Soil Health – Avoiding stubble burning helps retain soil fertility and reduces long-term damage.

4. Reduced Carbon Footprint – Pellets replace coal and fossil fuels in industries, cutting emissions.

5. Government Support – With NTPC’s biomass co-firing initiative and subsidies, pellet production is highly encouraged.

🌍 Supporting India’s Clean Energy Goals

The Indian government aims to reduce dependence on fossil fuels and increase renewable energy usage. NTPC and other power plants have already started biomass co-firing, where pellets are mixed with coal. Yulong-Gattuwala is playing a crucial role in supplying reliable pellet machines that meet this demand.

By converting crop waste into fuel, farmers become partners in India’s energy transition while also reducing pollution levels drastically.

✅ Why Farmers Trust Yulong-Gattuwala

• Proven Technology – Machines are robust and built for heavy-duty agro residues.

• End-to-End Solutions – From plant setup to subsidy guidance, farmers get complete support.

• Low Maintenance – Designed for easy use and long life, reducing downtime.

• Strong Network – Yulong-Gattuwala machines are already installed across multiple states in India.

Pollution caused by stubble burning is a serious issue, but it can be tackled with innovative solutions. Yulong-Gattuwala biomass pellet machines empower farmers to manage waste efficiently, create clean energy, and reduce environmental damage.

By choosing pellet technology, farmers are not just protecting the environment—they are securing a sustainable future for agriculture and contributing to India’s green energy mission.

👉 Yulong-Gattuwala truly transforms pollution into opportunity, making agriculture cleaner and more profitable.

📞 Interested in setting up a biomass pellet plant in India? Contact Gattuwala Energy for expert consultation, equipment, and government subsidy support.