- August 25, 2025

India, being an agricultural nation, generates millions of tonnes of crop residue every year. Rice husk, wheat straw, sugarcane bagasse, cotton stalks, and paddy straw often go to waste, with a large portion burned in open fields. This not only causes severe air pollution but also contributes to greenhouse gas emissions. A sustainable solution to this problem lies in converting agriculture residue into biomass power, and Yulong-Gattuwala Pellet Plants are leading the way in making this possible.

The Problem of Agricultural Waste in India

According to government data, India produces over 500 million tonnes of crop residue annually. Instead of being utilized, much of this residue is either left to decompose or openly burned by farmers, especially in states like Punjab, Haryana, and Uttar Pradesh. Stubble burning leads to smog, poor soil health, and wasted energy potential.

This is where biomass pellet plants become a game-changer, as they transform agro residue into a renewable energy source.

Converting Agro Waste into Biomass Pellets

The process of turning crop waste into biomass power involves pelletization. Yulong-Gattuwala, a trusted pellet machine manufacturer and supplier, provides complete solutions for farmers, entrepreneurs, and industries.

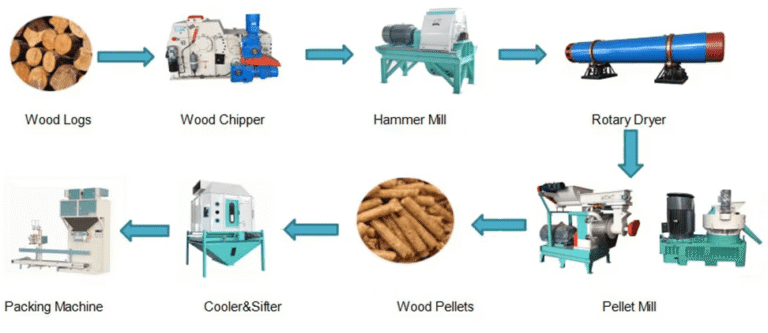

Here’s how the process works:

- Collection of Raw Material – Residues like rice husk, paddy straw, corn stalk, or bagasse are gathered.

- Drying – Moisture is reduced to 10–15% using advanced flash dryers.

- Grinding – Hammer mills crush the residue into fine powder for uniform pellet quality.

- Pelletizing – Yulong-Gattuwala pellet machines compress the biomass under high pressure into dense, energy-rich pellets.

- Cooling & Packaging – Finished pellets are cooled and packed for transportation.

These pellets can then be used in boilers, power plants, or even exported as renewable fuel.

⚡ Why Biomass Power Matters

Biomass pellets provide:

• Sustainable energy – Reduces reliance on coal and fossil fuels.

• Reduced pollution – Minimizes stubble burning and air contamination.

• Economic benefits – Farmers earn extra income by selling crop residue.

• Energy security – Boosts India’s renewable energy share.

The Indian government and organizations like NTPC are already promoting biomass co-firing in thermal power plants, further increasing demand for quality pellets.

Yulong-Gattuwala: Driving the Change

Yulong-Gattuwala pellet plants are designed to handle India’s tough agro residues. Here’s why they stand out:

• High efficiency: Machines with world-class technology for better pellet output.

• Durability: Built to withstand heavy use with Indian raw materials.

• Turnkey solutions: Complete support from plant setup to operations.

• Subsidy guidance: Assistance in availing government subsidies on biomass projects.

Many successful installations across India show that Yulong-Gattuwala is at the forefront of converting agriculture residue to biomass power.

The Future of Biomass Power in India

With increasing emphasis on clean energy, the market for biomass pellets is expected to grow exponentially. Agro waste, instead of being a liability, is turning into an opportunity. Entrepreneurs, industries, and farmers can all benefit from adopting pellet technology.

By choosing Yulong-Gattuwala pellet machines, you are not only investing in a profitable business but also contributing to India’s green energy revolution.

The journey from agriculture residue to biomass power is more than just technology—it’s about creating a cleaner, greener, and more sustainable India. With Yulong-Gattuwala pellet plants, the transformation of farm waste into renewable fuel is not just possible, but profitable.

Biomass is no longer a by-product—it’s the future of energy. And the government is ensuring that future arrives faster.

📞 Interested in setting up a biomass pellet plant in India? Contact Gattuwala Energy for expert consultation, equipment, and government subsidy support.