- July 4, 2025

As the global energy landscape shifts toward sustainability, biomass pellet machines have emerged as a key solution for converting agricultural waste and biomass into renewable fuel. With increasing demand for green energy and waste management, top biomass pellet machine manufacturers in India are taking innovative steps to stand out in this competitive industry. This article explores what leading companies are doing differently to enhance machine performance, reliability, and efficiency—focusing on sustainability, government support, and market demand.

Understanding Biomass Pellet Machines

Biomass pellet machines are used to compress biomass materials—such as sawdust, rice husk, agricultural residues, and wood chips—into solid fuel pellets. These pellets are widely used in heating systems, industrial boilers, and even power generation plants. The growing emphasis on clean fuel and waste-to-energy initiatives makes pellet machines a promising investment for both large and small enterprises.

Why Biomass Pellets?

• 🌍 Environmentally Friendly: Biomass pellets reduce carbon footprints and offer a cleaner alternative to fossil fuels.

• ♻️ Waste Utilization: Efficiently uses agricultural and industrial waste.

• 🔥 High Energy Density: Pellets produce more consistent and powerful energy output.

• 💰 Cost-Effective: Long-term savings in fuel costs for industries.

What Top Manufacturers Are Doing Differently

1. Investing in R&D for Improved Efficiency

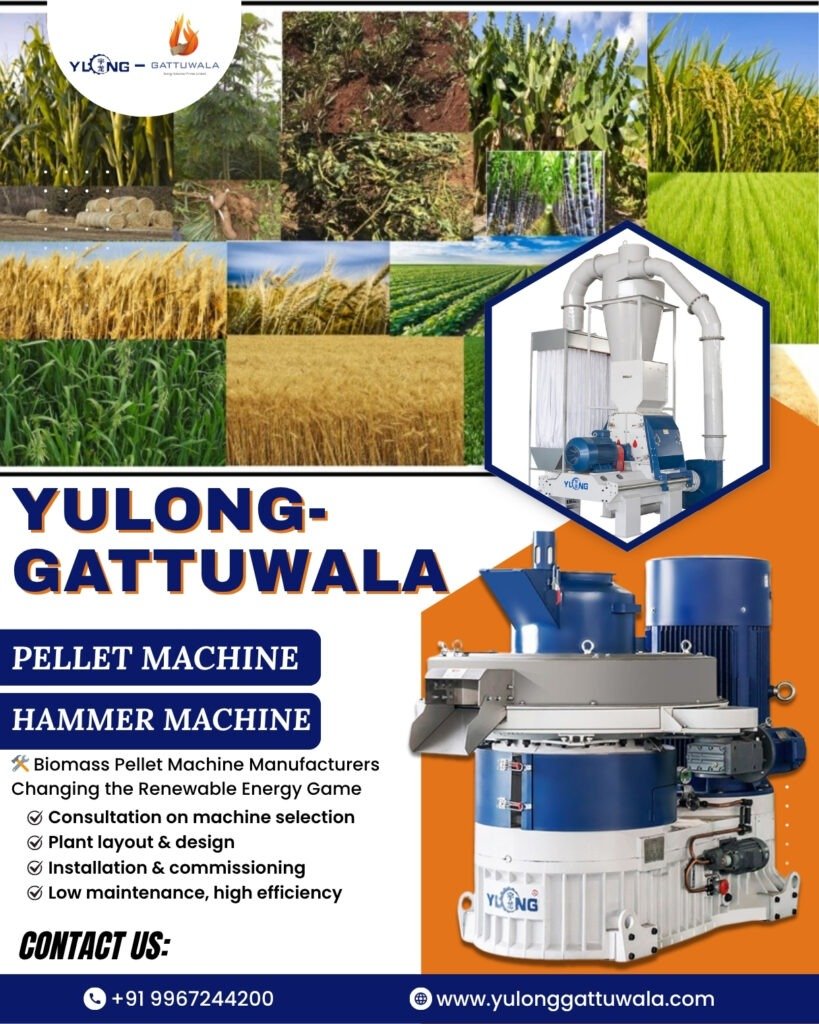

Leading biomass pellet machine manufacturers like Yulong, Gattuwala Energy, and others are heavily investing in research and development (R&D). They are creating high-efficiency die and roller designs, advanced gearbox mechanisms, and better lubrication systems. The result? Lower energy consumption and longer machine life.

2. Automation and Smart Monitoring

Modern machines from top manufacturers now include automated feeding systems, real-time data monitoring, and fault detection technology. This reduces labor dependency and ensures consistent production without frequent manual interventions.

3. Durability & Low Maintenance

The best pellet machines today use premium steel alloys and high-precision engineering for long-lasting components. Wear parts such as dies, rollers, and bearings are designed to withstand continuous operation, minimizing downtime and operational costs.

4. Customization Based on Feedstock

Different regions in India have different types of agricultural waste—rice husk in Punjab, bagasse in Maharashtra, and cotton stalks in Gujarat. Top suppliers now offer customized biomass pellet machines tailored to the specific feedstock and moisture content of the material, ensuring higher output and efficiency.

Government Tenders & Subsidies: A Growth Catalyst

Top manufacturers are also working closely with government agencies to participate in tenders, clean energy programs, and state-run biomass initiatives. Thanks to policies under the Ministry of New and Renewable Energy (MNRE), businesses can now access subsidies for biomass pellet projects, encouraging wider adoption.

Manufacturers like Gattuwala Energy provide end-to-end solutions, including project report preparation, subsidy assistance, and post-installation support—making them highly preferred partners.

Global Market Reach

Another differentiator is export capability. Indian manufacturers are now serving clients in Africa, Southeast Asia, and the Middle East, offering cost-effective and reliable machines that compete with European counterparts.

Companies focusing on international quality certifications, robust packaging, and multilingual manuals are expanding their global footprint rapidly.

Training & After-Sales Support

Even the best machine is only as good as its operator. Leading pellet machine suppliers in India offer on-site training, technical documentation, and remote support to ensure machines run at peak performance. This after-sales service boosts customer confidence and long-term satisfaction.

Sustainability Focus

Eco-conscious manufacturers are not just selling machines—they’re promoting a vision. Their plants are often powered by solar energy, use zero-waste manufacturing processes, and focus on building a circular economy around biomass utilization.

Choosing the Right Supplier

When selecting a biomass pellet machine manufacturer in India, consider the following:

• ✅ Proven track record with installations across India

• ✅ Availability of spare parts and service centers

• ✅ Compliance with pollution control norms

• ✅ Transparent pricing and warranty coverage

In conclusion, the future of green energy is being shaped by how biomass pellet machine manufacturers evolve their technology and services. The top players in India are not just selling machines—they are delivering complete energy solutions that empower industries to shift towards sustainable production.

If you’re planning to enter the biomass pellet market or upgrade your current plant, partnering with a trusted, innovation-driven manufacturer is the smartest move. From fuel savings to environmental compliance, the benefits are undeniable.

📞 Interested in setting up a biomass pellet plant in India? Contact Gattuwala Energy for expert consultation, equipment, and government subsidy support.